1. Dab tsi yogEVA Kub Melt Adhesive Film?

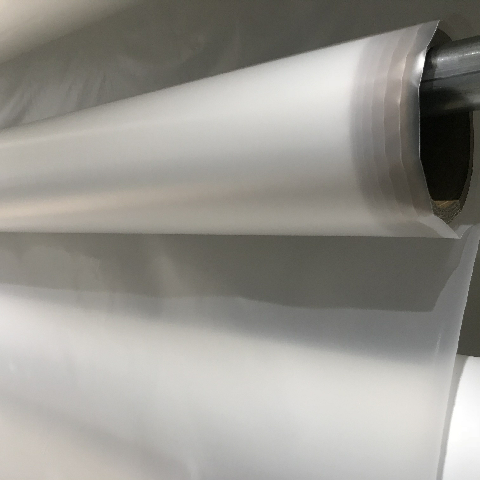

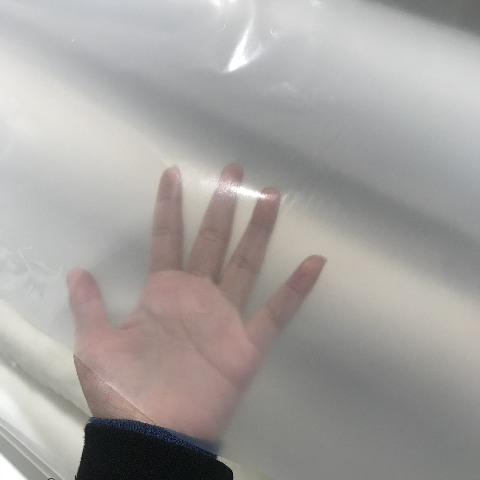

Nws yog ib qho khoom, thermoplastic nplaum cov khoom nkag rau hauv nyias zaj duab xis lossis daim ntawv web.

Nws lub hauv paus polymer yogEthylene Vinyl Acetate (EVA)copolymer, feem ntau compounded nrog tackifying resins, waxes, stabilizers, thiab lwm yam modifiers.

Nws yog qhib los ntawm tshav kub thiab siab, melting los tsim ib tug muaj zog nplaum daim ntawv cog lus thaum txias.

2. Cov khoom tseem ceeb:

Thermoplastic:Melts thaum cua sov thiab solidifies thaum txias.

Solvent-Free & Eco-Friendly:Tsis muaj cov organic sib txuas (VOCs), ua kom huv thiab nyab xeeb dua li cov kua nplaum ua kua nplaum.

Fast Bonding:Kev ua kom thiab kev sib txuas ua ke tshwm sim sai heev thaum tshav kub thiab siab siv.

Qhov zoo pib Tack:Muab lub zog pib tuav thaum molten.

Flexibility:EVA-raws li cov yeeb yaj kiab feem ntau khaws cov kev hloov pauv zoo tom qab kev sib raug zoo, ua kom zoo rau cov substrates.

Wide Adhesion Range:Bonds zoo rau ntau yam ntxeem tau thiab tsis ntxeem tau cov ntaub ntawv (fabrics, foams, plastics, ntoo, hlau).

Kev ua haujlwm yooj yim:Tau tshaj cov txheej txheem kev lag luam lamination thiab cov cuab yeej sib txuas.

Nqi-zoo:Feem ntau cov tshuaj nplaum qis dua piv rau lwm hom HMAM (xws li PA, TPU).

3. Cov ntawv thov tseem ceeb:

Textile & Apparel:

Laminating fabrics (xws li, interlinings rau dab tshos, cuffs, waistbands).

Hemming thiab seam sealing.

Txuas appliqués, thaj ua rau thaj, thiab daim ntawv lo.

Bonding non-woven fabrics (xws li, hauv cov khoom tu cev, lim dej).

Cov khau khiab xws li ntiv taw puffs, txee, insoles, thiab hauv ob sab phlu.

Txuas sab saum toj rau midsoles lossis outsoles (feem ntau ua ke nrog lwm cov nplaum).

Laminating hluavtaws tawv thiab textiles.

Ntim:

Tshwj xeeb ntim lamination (xws li, ntawv / ntawv ci, ntawv / yas).

Sealing cartons thiab thawv.

Tsim cov thawv nruj.

Automotive & Tsheb thauj mus los:

Kev sib txuas ntawm sab hauv trim Cheebtsam (headliners, qhov rooj panels, ntaub pua plag, pob tw liners).

Laminating fabrics rau foams los yog composites.

Ntug banding thiab sealing.

Rooj tog & Upholstery:

Bonding ntaub rau ua npuas ncauj padding.

Ntug sealing thiab lamination hauv txaj thiab cushions.

Laminating hniav nto.

Technical Textiles & Industrial Laminates:

Bonding txheej nyob rau hauv filtration media.

Laminating geotextiles.

Tsim cov ntaub ntawv sib xyaw rau ntau yam kev lag luam siv.

DIY & Crafts:(Lower melt point variants)

Bonding cov ntaub ntawv rau cov haujlwm hobby.

Npuag crafts thiab embellishments.

4. Kev ua haujlwmTxoj kev:

5. Flatbed Lamination:Siv cov cua kub platen presses.

Nruam Roll Lamination:Siv cov calendar rolls los yog nip rollers.

Contour Bonding:Siv cov cuab yeej tshwj xeeb cua sov rau cov duab tshwj xeeb.

Ultrasonic Activation:Siv lub zog ultrasonic los yaj cov yeeb yaj kiab hauv zos (tsawg dua rau EVA dua li lwm hom).

Txheej txheem:Muab cov zaj duab xis ntawm substrates -> Siv cov cua sov (melting zaj duab xis) -> Siv siab (kom tiv thaiv kev sib cuag & ntub dej) -> Txias (kev sib koom ua ke thiab kev sib koom ua ke).

6. Qhov zoo ntawm EVA HMAM:

Ntxuav thiab yooj yim los tuav (tsis muaj kev ntxhov siab, tsis muaj plua plav).

Raws li thickness thiab nplaum tis.

Tsis tas yuav ziab / kho lub sijhawm tom qab kev sib txuas.

Zoo cia ruaj khov nyob rau hauv tej yam kev mob.

Zoo sib npaug ntawm adhesion, yooj, thiab nqi.

Qhov kub ua haujlwm qis dua piv rau qee qhov HMAMs.

6. Kev txwv / kev txiav txim siab:

Temperature Sensitivity:Daim ntawv cog lus tuaj yeem muag lossis ua tsis tiav ntawm qhov kub siab (feem ntau txwv rau <~65-80 ° C / 150-175 ° F txuas ntxiv siv, nyob ntawm kev tsim).

Chemical Resistance:Feem ntau tsis zoo rau cov kuab tshuaj, roj, thiab tshuaj muaj zog.

Creep:Nyob rau hauv tas li load, tshwj xeeb tshaj yog nyob rau hauv lub kub kub, cov khoom sib txuas tej zaum yuav creep (me ntsis deform).

Moisture Resistance:Kev ua tau zoo tuaj yeem hloov pauv raws li kev tsim; tsis inherently waterproof zoo li tej PUR films.

Substrate Compatibility:Thaum dav, adhesion rau cov khoom siv hluav taws xob tsawg heev (xws li PP, PE) feem ntau xav tau kev kho deg lossis cov qauv tsim tshwj xeeb.

Xaus:

EVA Kub Melt Adhesive Film yog ntau yam, muaj txiaj ntsig zoo, thiab cov neeg siv kev sib raug zoo sib raug zoo siv dav hauv textiles, khau, ntim, tsheb sab hauv, rooj tog zaum, thiab kev lag luam lamination. Nws lub zog tseem ceeb yog nyob rau hauv nws yooj yim ntawm kev ua, zoo yooj, muaj zog pib tack, thiab hnyav-dawb yam. Thaum nws qhov kub thiab tshuaj tiv thaiv ua rau qee qhov kev txwv, nws tseem yog qhov kev xaiv tseem ceeb rau cov ntawv thov uas cov yam ntxwv no tsis yog qhov tseem ceeb thiab qhov txiaj ntsig zoo yog qhov tseem ceeb.

Post lub sij hawm: May-29-2025