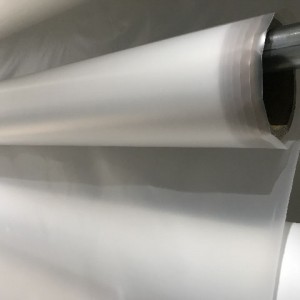

Kub yaj nplaum zaj duab xis rau insole

Nws yog TPU kub yaj nplaum zaj duab xis uas tsim nyog rau kev sib txuas ntawm PVC, tawv tawv, ntaub, fiber ntau thiab lwm yam ntaub ntawv uas yuav tsum tau ua kom sov. Feem ntau nws yog siv los tsim PU npuas insole uas yog ib puag ncig-phooj ywg thiab tsis muaj tshuaj lom.

Piv nrog kua nplaum nplaum, cov khoom no coj zoo rau ntau yam xws li kev sib raug zoo evironment, daim ntawv thov txheej txheem thiab kev txuag nqi. Tsuas yog thaum tshav kub kub-xovxwm ua, tuaj yeem lamination tau paub.

Peb tuaj yeem ua cov khoom no nrog lossis tsis muaj substrate, raws li cov neeg siv khoom xav tau. Feem ntau, cov tshuab laminating loj loj yog siv los ua cov ntaub npuag rov qab. Cov neeg siv khoom feem ntau siv tsis muaj substrate, lossis qee cov neeg siv khoom xav tau ib zaj duab xis nrog pe zaj duab xis substrate thaum siv lub tshuab pav ca laminating. Peb kuj tuaj yeem muab qhov no. Cov yeeb yaj kiab ua los ntawm TPU yog mos thiab ntxuav, uas piav qhia vim li cas cov khoom no nrov heev. Tsis tas li ntawd, feem ntau ntawm cov qauv no yog 500m yob, qhov dav li niaj zaus yog 152cm lossis 144cm, lwm qhov dav kuj tuaj yeem kho tau.

1. Mos tes zoo li: thaum thov ntawm insole, cov khoom yuav muaj ib tug mos mos thiab xis hnav.

2. Dej-ntxuav resistant: Nws tuaj yeem tiv taus yam tsawg 10 zaug dej-ntxuav.

3. Tsis muaj tshuaj lom thiab ib puag ncig-phooj ywg: Nws yuav tsis tso cov ntxhiab tsw ntxhiab thiab yuav tsis muaj kev cuam tshuam tsis zoo rau cov neeg ua haujlwm noj qab haus huv.

4. Yooj yim rau txheej txheem ntawm cov cav tov thiab txuag nqi zog: Nws pib lamination tshuab ua, txuag nqi zog.

5. Tsawg melting point: nws suits lamination rooj zoo li ntaub nrog kub tsis kam.

PU ua npuas ncauj insole

Kub yaj nplaum zaj duab xis yog dav siv ntawm insole lamination uas yog nrov txais tos los ntawm cov neeg siv khoom vim nws cov mos mos thiab xis hnav zoo. Tsis tas li ntawd, Hloov cov kua nplaum ib txwm siv, cov nplaum nplaum nplaum nplaum tau dhau los ua cov khoom siv tseem ceeb uas ntau txhiab tus neeg tsim khoom siv khau tau siv rau ntau xyoo.

L341B kub yaj nplaum zaj duab xis kuj tseem siv tau ntawm lub tsheb lev, hnab thiab lub nra, ntaub lamination.Raws li nws yog hais txog kev sib txuas ntawm PU ua npuas ncauj khoom, peb muaj cov kev daws teeb meem. Tshwj xeeb tshaj yog nyob rau hauv kev sib raug zoo ntawm foamed board khoom, peb lub tuam txhab daim ntawv thov kev daws teeb meem nyob rau hauv lub cheeb tsam no tau heev mature. Txog tam sim no, peb tau mus txog kev koom tes nrog ntau dua 20 lub tuam txhab lub nra hauv tsev thiab txawv teb chaws, thiab daim ntawv thov kub yaj nplaum zaj duab xis hauv lub nra thiab lub hnab ntim tau ua tiav cov lus teb zoo heev.